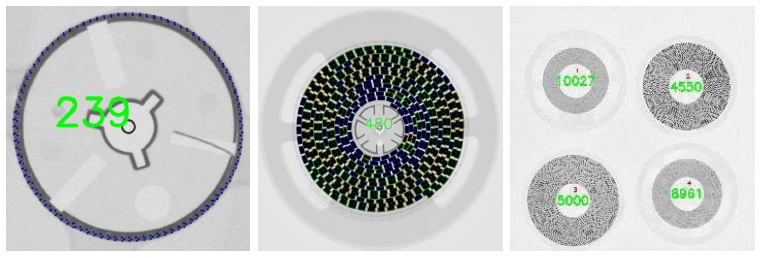

1. Accuracy: 99.99% (0201);

2. Compatible minimum device type:01005 (unit: inch);

3. The highest pointing speed: about 6-10 seconds/4 plate

4. Calculated based on the minimum size of 01005 (unit: inch) 20,000 points;

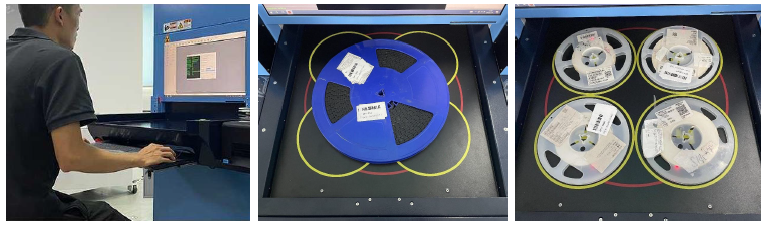

5. 7" tray four trays at the same time feeding speed: about 8 seconds;

6. Time including loading and unloading: about 11 seconds;

7. Support multiple sizes of material inventory (7"~15");

8. With X-Ray PCB detection function and X-Ray other assembly product detection function;

9. Support automatic data upload to the cloud and synchronization, update the database every month, the longer the time, the more accurate;

10. One-button operation, Intuitive and easy-to-use GUI;

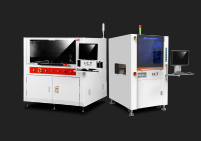

11. Minimize investment cost (super normal introduction cost);

12. High safety, with EU CE Certificate, International Quality Management System ISO, and AERB Certificate for X-ray.

TOP Advantage of X-Ray Component Counting Machine:

1. Simple: combined with advanced international concepts, easy to understand, easy to learn, easy to maintain;

2. Save time: warehouse management is more efficient, can save 10-20 times the time cost;

3. Hedging: Import hardware configuration, low failure rate in production, more than a decade service life;

4. Safety: Based on the general rules of international design, the highest security level;

5. Stable: mature software, hardware and top production processes ensures stability of each equipment.

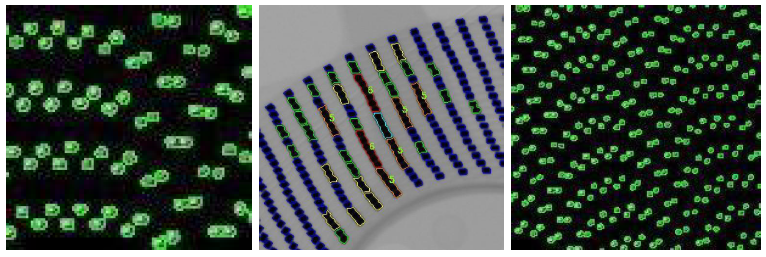

Apply the AI-optimized counting algorithm to realize spot inspection of various materials: standard SMD, dicing tape, JEDEC/Matrix tray, MELF, Aluminum Caps, Soic, To, BGA/CPU, Tantal, filter and other parts. Four material pallets can be counted at the same time, and it only takes 8 seconds to complete, which shortens the counting time of parts pallets, automatically uploads data to the cloud, regularly updates the database, and links with the factory ERP/MES system, greatly saving time and cost. Easy to manage.

English

English