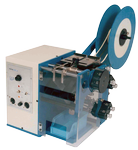

Lead Former for Bulk or Loose RADIAL Components (CF-10)

Company Information:

Name: |

Lead Former for Bulk or Loose RADIAL Components (CF-10) |

Category: |

|

Offered by: |

|

|

View Lead Former for Bulk or Loose RADIAL Components (CF-10) |

Lead Former for Bulk or Loose RADIAL Components (CF-10) Description:

Form & Cut 2-, 3-, 4-, 5-, and 7-leaded Radial Components

- Capable of forming loose radial components at rates up to 5,000 parts per hour with a variable speed motor.

- Feed components by hand or with tubes (TO-220s)

- Reduce setup time with quick change tooling and repeatable station settings.

- Forms bulk radial-leaded components to numerous form styles.

The CF-10 Loose/Bulk Radial Lead Former is capable of forming loose radial components at rates up to 5,000 parts per hour with its variable speed motor. Its three die stations are independently adjustable in height. The unique shuttling mechanism enables a wide variety of components to be formed:

• TO-202s • LEDs • TO-218s • Capacitors (uniform body shape) • TO-220s • TO-126s • TO-92s

The tooling and shuttles are easily replaced in minutes, minimizing the change-over time from one set up to another. Loose radial components with 2 or 3 leads are fed into the machine manually. A tube feeder for TO-220s with 3, 4, 5, or 7 leads is also available. The components are fed via the vibratory track, shuttled into position, and captured by the use of two timing belts.

A component is aligned in the shuttle and transported into position to the fi rst of three die stations. The vertically adjustable die stations feature standard micrometer scales with display increments to 0.001” (0,025 mm). When one cycle is complete, the machine indexes and presents the next component to be formed. Waste leads exit through either a chute or, in the case of TO220s, by means of a vacuum system. Formed components are collected in a parts bin.

CF-10 component forming dies are precisely manufactured and are available to form a wide variety of component types. CF-10 forming dies are easily installed and can be ordered to form various component configurations. Custom dies for specific forming jobs are also available from GPD Global. Please contact GPD Global +1(970) 245-0408

GPD Global's Precision Lead Formers

GPD Global Axial and Radial precision lead formers have been industry standards since the 1980s, consistently outperforming and outliving the competition.

The CF-8 for Axial components and the CF-9 for taped Radial components are capable of forming a variety of forms including flushmount, standoff, and lock-in (dependent on inserted dies). The CF-10 handles 2- to 7-leaded Radial components in bulk or loose form and is capable of a variety of forms including flushmount, standoff, lock-in, and spread forms.

View Lead Former for Bulk or Loose RADIAL Components (CF-10)

Lead Former for Bulk or Loose RADIAL Components (CF-10) was added in Apr 2015

Lead Former for Bulk or Loose RADIAL Components (CF-10) has been viewed 1742 times

15 More Products from GPD Global  :

: