BGA Rework Machine for soldering and desoldering. Hot Air BGA rework station for printed circuit board repair.

Company Information:

Name: |

BGA Rework Machine for soldering and desoldering. Hot Air BGA rework station for printed circuit board repair. |

Category: |

|

Offered by: |

|

|

|

BGA Rework Machine for soldering and desoldering. Hot Air BGA rework station for printed circuit board repair. Description:

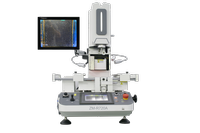

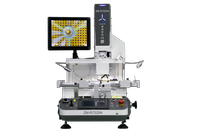

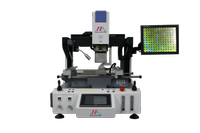

SV560A BGA Rework Station Demo

BGA Rework Stations from the BGA Experts with over 25 years rework process experience and customer support!

For high volume BGA Rework on even the largest computer and networking boards!

The model SV560A has a high resolution optical system for placement of components as small as 1mm. With it's rapid heat infrared area heater it can rework boards as large and heavy circuit boards.

Features:

- Auto soldering and mounting function.

- Three heaters( top and bottom hot air heater, bottom area rapid heat IR heater.

- Powerful cross flow fans cool the bottom heating area rapidly with stable speed.

- Color optical system with functions of split vision, zoom in/out and micro-adjust.

- Auto focus and software operation function,1.3 million pixel high-definition camera.

- 15’’ high-definition LCD monitor.

- Five Thermal Couple Inputs

- Six Zone Rapid IR under heater.

- Fully self contained with PLC control. No need for external air.

- Plug in and ready to use.

- 1 Year Parts Warranty

- 1-Day Training

- Lifetime Technical Support

Features:

1. Hot air heater head and mounting head are designed 2 in 1, with auto pick-up,auto solder,auto desolder and auto placement function.

2. Three heaters( top/bottom hot air heater, bottom IR heater) heating independently, with auto protectionfunction while heating abnormally ,time and temperature can be displayed digitally on touch screen;

3. Top heating system and cooling system are designed 2 in 1,(which is our patent design), temperature controlled accurately and evenly.

4. Bottom heater is IR wave gilding heater plate, with high temperature glass, temperature increasing anddecreasing rapidly;

5. Powerful cross flow fans cool the bottom heating area rapidly with stable speed;

6. Megapixel HD Color optical camera system with functions of split vision, zoom in/out and micro-adjust, equipped with aberration detection device; with auto focus and software operation function,

7. Large movable bottom IR heating area, PCB clamps can be adjusted along with X & Y table

flexibly.

8. Embedded industrial computer, touch screen interface, PLC control, real-time temperature curve display, can analyze the practically-tested profile, and compare them with the history saved profiles;

9. Built-in vacuum pump,pick-up nozzle 360°rotated by motor.

12. 8 segments of temperature control setting, profile saving unlimited.

10. Suction nozzle can identify material and mounting height automatically, and can control the air pressure within a small range ;

11.With different alloy nozzles,using high-temperature magnet to locate,easy to replace and able to locate in any angle.

Technical parameter:

|

PCB size |

W20*D20~W550*D500 |

|

Workable area |

W550*D500mm |

|

PCB thickness |

0.5~4mm |

|

Applicable BGA |

1*1~80 *80mm |

|

Working table adjustment |

±10mm Forward/backward,±10mm left/right |

|

PCB locating way |

Jig |

|

Placement precision |

±0.01mm |

|

Min.pitch of BGA ball |

0.15mm |

|

Gross power |

5600W |

|

Bottom IR preheat |

3600W |

|

Top heater |

1200W |

|

Bottom heater |

800W |

|

Max BGA weight |

80g |

|

Power supply |

Single phase 220V,50/60Hz, |

|

Machine dimension |

L750*W705*H800mm |

|

Weight |

Approx. :100kg |

BGA Rework Machine for soldering and desoldering. Hot Air BGA rework station for printed circuit board repair. was added in Mar 2016

BGA Rework Machine for soldering and desoldering. Hot Air BGA rework station for printed circuit board repair. has been viewed 3123 times

20 More Products from Precision PCB Services, Inc  :

:

.jpg)

.png)