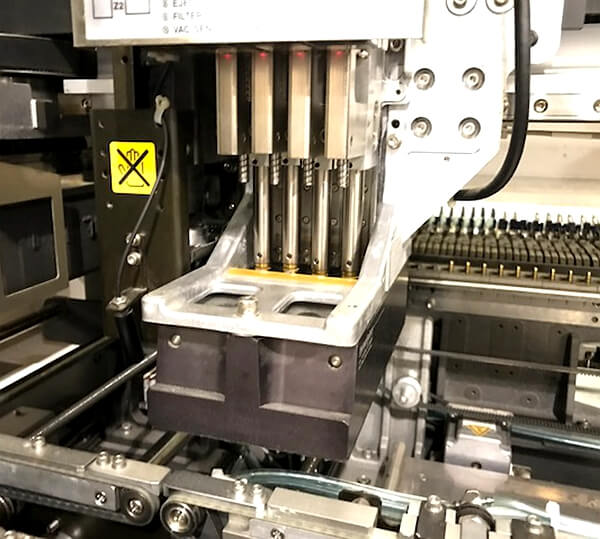

JUKI KE-2030 chip mounter

Company Information:

Name: |

JUKI KE-2030 chip mounter |

Category: |

|

Offered by: |

|

JUKI KE-2030 chip mounter Description:

JUKI KE-2030 chip mounter

Mounting Speed: 20000CPH

PCB size: 330mmX250mm

Weight 1400KG

Product description: JUKI KE-2030 chip mounter, Mounting Speed: 20000CPH, PCB size: 330mmX250mm, Weight 1400KG

JUKI 2030 is 20000CPH can achieve high-speed performance "double-chip high-speed placement machine."

Not only can be used around 2 patch head to mount two substrates at the same time,

but also to achieve the same type of mounting the highest efficiency,

The equivalent of two JUKI 2010.

1) PCB size: 330mmX250mm

2) Can be attached to the component range: 0402,0603 chip -26.5X11mm or 20mm square components

3) The number of stations: 60 x 2

4) theoretical chip speed: 20000 (grain / hour)

5) Mounting accuracy: Laser identification ± 0.08mm

6) Size and weight: L1900 / W1476 / H2000 & 6000KG

7) Weight 1400 (kg)

Power three-phase AC200-415 (V)

8) Patch speed 19000CPH (grain / hour)

9) Resolution ± 0.05mm (mm)

Manufactured in 2000,

PCB size: 330mmX250mm

Components can be affixed to range: 0402,0603 chip-26.5X11mm or 20mm square components

Feed station number: 60 x 2

Theory Chip Speed: 20000 (tablets / hour)

Placement accuracy: ± 0.08mm laser identification

Size and weight: L1900/W1476/H2000 & 6000KG

Power and gas supply: 3PH, 200V, 5KVA

Configuration: 0603 2 sets of each nozzle; Manual CD-ROM 1

Specifications

Vintage:2004

Placement:20,000cph

2 multi nozzle laser heads(8 nozzles)

From: 0603 (0201)chip to 26.5 x 11mm chip or 20mm square chip

Simultaneous placement of components onto two boards

Medium board size: 330 x 250mm

Large board size: 410 x 360mm

Extra large board size: 510 x 460mm

Applicable component height: 6mm, 12-20mm

Component size: 25mm, 0603 chip, from 1005 chip

to 20mm square chip or 26.5 x 11mm chip.

From 1005 chip to 50mm square chip or 50 x 150mm chip

Component placement speed: chip, IC: 20,000cph

Component placement accuracy: Laser recognition +/- 0.08mm

Vision Recognition

Max. unique components: 120 per side using 8mm tape feeders

Feeders type available: tape- 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, and 56mm.

Stick/ bulk/ tray not available

Power: 3 phase 200/220/240 or 380 VAC

Compressed Air: 71psi

Operating System: Windows NT

Programming Methods: On line: teach with placement head, teach camera, key board only

Off Line: keyboard entry, CAD data conversion with optional software

Program Size: Maximum 3000 placements per circuit, not to exceed 10,000

Maximum 100 non-matrix or 400 matrix circuits per PCB.

Data entry resolution: X/Y axis 0.0004” (o.01mm)

Teta axis (rotation) 0.05

Entry in millimeters or inches

Self Calibration: Self calibration routine allows operator

to recalibrate at anytime in just minutes

Up and Down line connection: SMEMA standard

Teach Camera: Allows teaching of pick and placement location with

one of two CCD cameras mounted on the head assembly

Auto Tool Changer: The two tool changer hold up to fourty-one (41) vacuum nozzle

Seventeen (17) vacuum nozzles are standard (8x502, 8x504, 1x508)

Placement Heads: Two (2) Multi- Nozzles Laser Align (MNLA) high speed assembley

head (total of 8 nozzles) driven by a overhead X/Y gantry positioning

System with closed loop twin AC servo motors and magnetic linear encoders

Component Pick and Placement Method: Pickup and placement is

performated via vacuum nozzle with programmable pick and placement force

Component Centering: Non Contact TouchLess Centering (TLC) using LaserAlign Sensor

Component Detection: Vacuum Sensor and Laser

Keywords:

Professional SMT machine supplier. If you have any needs, please contact us.

Hanwha Pick and Place Machine:XM520, HM520, HM510, Excen PRO, Decan S2, Decan S1, SM485P, SM482 Plus, SM481 Plus, SM471 Plus

Yamaha Pick and Place Machine: YRM20DL, YRM20, YSM40R, YSM20R, YSM20WR, YSM10, F8S, YS12F, YG12, YG100RA, YS24F

JUKI Pick and Place Machine: LX-8, RX-8, RX-7R, RX-7, RS-1R, RS-1, RS-1XL,JM-20, JM-100, FX-3RA, KE-3010A, KE-3020VA

Panasonic Pick and Place Machine: NPM-GH, NPM-DX, NPM-D3A, NPM-D3, NPM-WX/WXS, NPM-TT2, AM100, VM101, VM102

FUJI Pick and Place Machine: AIMEX III, AIMEX R, NXT III, NXTR-S, NXTR-A, NXT M6 III, NXT M6 Ⅱ, NXT M3 III, NXT M3 Ⅱ,

Siemens Chip Mounter: SIPLACE XS Series, SIPLACE SX Series, Siplace DX Series, SIPLACE TX Series,

SMT Stencil Printer: GKG, DEK, JUKI, FUJI, Yamaha, Panasonic, SMT Glue Dispenser, Semi-Auto stencil printer,

SMT Reflow oven: 6 Zones, 8 Zones, 10 Zones, 12 Zones, Heller, Ersa, JT

Insert Plug-in machine: Hanwha, JUKI, Yamaha, Panasonic, Offline Insert Plug-in machine, Vertical Plug-in machine, Heterotypic Plug-in machine

Wave Soldering Machine: Dual Rail, lead free, Nitrogen, Ersa, JT

SMT Inspection machine: Saki SPI/AOI, Koh Young SPI/AOI, JUKI SPI/AOI, Omron SPI/AOI, Yamaha SPI/AOI, Flying Probe Testing Machine, X-Ray Inspection Machine, In-Circuit Tester,

SMT Peripheral Equipment: PCB Loader, PCB Unloader, PCB Conveyor, PCB Transfer Shuttle Conveyor, Auto BGA Rework Station, PCB loader Buffer Stocker, PCB Cleaning Machine, SMT Nozzle Cleaning Machine, PCB Separator Depanelizer Machine, Automatic inline Labelling Machine, SMT Screen Developing and Stripping Machine, SMT Ionic Contamination Tester, SMT Camera Module Cleaning Machine, Reflow Oven Cooler Cleaning Machine, SMT Fixture Cleaning Machine, PCB Stencil Cleaning Machine, PCB Laser Marking Machine, PCB Circuit Repair Machine, Thermal Profiler for reflow oven,

SMT Spare Parts: JUKI Feeder, Yamaha Feeder, Panasonic Feeder, Sansung/Hanwha Feeder, FUJI Feeder, Seimens Feeder, Mydata Mycronic Feeder, Feeder Storage Cart, Tray Feeder, Feeder Calibration jigs, JUKI Nozzle, Yamaha Nozzle, Panasonic Nozzle, Samsung/Hanwha Nozzle, FUJI Nozzle, Universal GSM Nozzle, Siemens SIPLACE ASM Nozzle, Mydata Nozzle, JUKI Spare parts, Yamaha Spare parts, Panasonic Spare parts, Samsung/Hanwha Spare parts, Siemens Spare Parts, FUJI Spare Parts, Mycronic Spare Parts,

SMT WORKSHOP LINE: SMT LOADER+ SMT printer+ SMT SPI+ SMT chip mounter+ SMT reflow oven

Add: No. 4, Yangyong Industrial Zone, Shapu Community, Songgang Street, Baoan District, Shenzhen China Tel: +86 -137 14564591 Skype:sales@effsmt.com E-mail:sales@effsmt.com

JUKI KE-2030 chip mounter was added in Jan 2024

JUKI KE-2030 chip mounter has been viewed 6 times

20 More Products from Efficient Technology Co., Ltd :