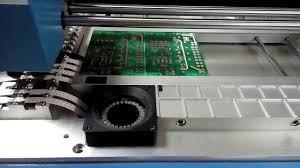

Samsung EXCEN PRO Pick and Place Machine

Company Information:

Name: |

Samsung EXCEN PRO Pick and Place Machine |

Category: |

|

Offered by: |

|

Samsung EXCEN PRO Pick and Place Machine Description:

High Speed:120,000 CPH

Ultra Slim Design with a Total Length of 1.25m

Applies High Rotary Modular Head

Side-view Vision System

Product description: China Samsung EXCEN PRO High Speed SMT Modular Chip Mounter agent-Good Price! Good Quality! Good Service!

Samsung EXCEN PRO Pick and Place Machine

As a high speed modular mounter that applies a high speed rotary head equipped with 16 nozzles, EXCEN realizes the world’s highest speed of 120,000 CPH among mounters of the same class as well as the world’s highest area productivity. In addition, it secures the reliability of fine chip placement by applying the function to monitor pre- and post-part placement, SVS (Side-view Vision System), and maximizes work convenience and actual productivity by applying various operation modes including non-stop device type change, mixed production of different boards as well as the SMART Feeder that realizes the world’s first Auto Splicing and Auto Loading functions.

120,000 CPH(Optimum)

Ultra Slim Design with a Total Length of 1.25m

Applies High Rotary Modular Head

Side-view Vision System(SVS) - Monitoring of pre- and post-part placement

Mixed Production of Different Boards/

Independent Production at the Front and Rear/

Non-stop Change-over of Device Types

High Speed and High Precision Feeder

SMART Feeder - The world’s first Auto Splicing and Auto Loading functions

HIGH PERFORMANCE:

Realizes the Highest Placement Speed of 120,000 CPH by Applying a High Speed Rotary Head Equipped with 16 Nozzles

Increases Actual Productivity by Reducing the Waiting Time Between Part Pickup and Placement to Zero(Cycloidal Motion)

Ultra Slim Design with a Total Length of 1.25m with Line Length and Area Productivity Being 50% and 200% of Those of Existing High Speed Lines, Respectively

HIGH RELIABILITY:

Side-view Vision System(SVS)

Secures fine chip placement reliability by adopting a function to monitor pre- and post-part placement status

Applies an Electrically Driven High Speed and High Precision Feeder

Enables a stable supply of parts through high performance servo control

Applies Samsung’s original high precision accuracy compensation algorithm and mechanism to minimize accuracy deviation over time

Automatic Pickup Position Correction Function

Feeders have a fiducial mark for automatic recognition of part pockets - Applies automatic feeding after reel replacement

The function to recognize the nozzle center after automatic nozzle change allows for automatic correction of nozzle offset

Automatic correction of pickup error during pickup through part center recognition offset

FLEXIBLE PRODUCTION:

Modular Head

Applies a modular head to allow an exchange between the high speed head and multi-functional head at the customers’ production site

Allows Simultaneous Production of Several Products Through Independent Production at the Front and Rear as well as Mixed Production of Different Types of Boards

Allows the Device Type to be Changed at a Lane without Stopping the Machine by Providing a Non-stop Device Type Change Function

Increased machine operation efficiency through advance preparation using a docking cart

Allows Maximization of Actual Productivity Through Various Operation Modes

Independent production at the front and rear mixed production of different boards, non-stop device type change, part placement in turns(Loading Time Zero)

EASY OPERATION:

Secures Feeder Operational Convenience by Applying a Super Slim Single Lane Electrically Driven Feeder

One-touch Exchange

Minimizes device type changing time by applying a one-touch exchange method to the docking cart, ANC and backup plate

SMART Feeder

Realizes the world’s first feeder equipped with Auto Splicing and Auto Loading functions · Applicable to reels with a small quantity of parts

Maximizes work convenience and actual productivity by automating the splicing process for part reel replacement which has been performed by hand

Keywords:

Professional SMT machine supplier. If you have any needs, please contact us.

Hanwha Pick and Place Machine:XM520, HM520, HM510, Excen PRO, Decan S2, Decan S1, SM485P, SM482 Plus, SM481 Plus, SM471 Plus

Yamaha Pick and Place Machine: YRM20DL, YRM20, YSM40R, YSM20R, YSM20WR, YSM10, F8S, YS12F, YG12, YG100RA, YS24F

JUKI Pick and Place Machine: LX-8, RX-8, RX-7R, RX-7, RS-1R, RS-1, RS-1XL,JM-20, JM-100, FX-3RA, KE-3010A, KE-3020VA

Panasonic Pick and Place Machine: NPM-GH, NPM-DX, NPM-D3A, NPM-D3, NPM-WX/WXS, NPM-TT2, AM100, VM101, VM102

FUJI Pick and Place Machine: AIMEX III, AIMEX R, NXT III, NXTR-S, NXTR-A, NXT M6 III, NXT M6 Ⅱ, NXT M3 III, NXT M3 Ⅱ,

Siemens Chip Mounter: SIPLACE XS Series, SIPLACE SX Series, Siplace DX Series, SIPLACE TX Series,

SMT Stencil Printer: GKG, DEK, JUKI, FUJI, Yamaha, Panasonic, SMT Glue Dispenser, Semi-Auto stencil printer,

SMT Reflow oven: 6 Zones, 8 Zones, 10 Zones, 12 Zones, Heller, Ersa, JT

Insert Plug-in machine: Hanwha, JUKI, Yamaha, Panasonic, Offline Insert Plug-in machine, Vertical Plug-in machine, Heterotypic Plug-in machine

Wave Soldering Machine: Dual Rail, lead free, Nitrogen, Ersa, JT

SMT Inspection machine: Saki SPI/AOI, Koh Young SPI/AOI, JUKI SPI/AOI, Omron SPI/AOI, Yamaha SPI/AOI, Flying Probe Testing Machine, X-Ray Inspection Machine, In-Circuit Tester,

SMT Peripheral Equipment: PCB Loader, PCB Unloader, PCB Conveyor, PCB Transfer Shuttle Conveyor, Auto BGA Rework Station, PCB loader Buffer Stocker, PCB Cleaning Machine, SMT Nozzle Cleaning Machine, PCB Separator Depanelizer Machine, Automatic inline Labelling Machine, SMT Screen Developing and Stripping Machine, SMT Ionic Contamination Tester, SMT Camera Module Cleaning Machine, Reflow Oven Cooler Cleaning Machine, SMT Fixture Cleaning Machine, PCB Stencil Cleaning Machine, PCB Laser Marking Machine, PCB Circuit Repair Machine, Thermal Profiler for reflow oven,

SMT Spare Parts: JUKI Feeder, Yamaha Feeder, Panasonic Feeder, Sansung/Hanwha Feeder, FUJI Feeder, Seimens Feeder, Mydata Mycronic Feeder, Feeder Storage Cart, Tray Feeder, Feeder Calibration jigs, JUKI Nozzle, Yamaha Nozzle, Panasonic Nozzle, Samsung/Hanwha Nozzle, FUJI Nozzle, Universal GSM Nozzle, Siemens SIPLACE ASM Nozzle, Mydata Nozzle, JUKI Spare parts, Yamaha Spare parts, Panasonic Spare parts, Samsung/Hanwha Spare parts, Siemens Spare Parts, FUJI Spare Parts, Mycronic Spare Parts,

SMT WORKSHOP LINE: SMT LOADER+ SMT printer+ SMT SPI+ SMT chip mounter+ SMT reflow oven

Add: No. 4, Yangyong Industrial Zone, Shapu Community, Songgang Street, Baoan District, Shenzhen China Tel: +86 -137 14564591 Skype:sales@effsmt.com E-mail:sales@effsmt.com

Samsung EXCEN PRO Pick and Place Machine was added in Jan 2024

Samsung EXCEN PRO Pick and Place Machine has been viewed 7 times

20 More Products from Efficient Technology Co., Ltd :