Automatic Samsung SM481 SMT Assembly line

Company Information:

Name: |

Automatic Samsung SM481 SMT Assembly line |

Category: |

|

Offered by: |

|

Automatic Samsung SM481 SMT Assembly line Description:

Samsung SMT Assembly line

Samsung PCB Assembly line

Samsung SMT production line

Samsung PCB production line

Product description: Full Automatic Samsung SM481 SMT Assembly line, with Smasung SM481 plus middle speed pick and place machine, this SMT assembly line is suitable for home appliance industry: air conditioners, refrigera

Automatic Samsung SM481 SMT Assembly line

Full Automatic Samsung SMT Assembly line, with Smasung SM481 plus middle speed pick and place machine, this SMT assembly line is suitable for home appliance industry: air conditioners, refrigerators, washing machines, water heaters, induction cookers, LED lamps, indoor lighting equipment, outdoor lighting equipment, industrial lighting

1. PCB loader

Micro computer controlled component ensures machine’s stable and reliable running.

Optional Fuji buttons interface or touch panel interface, convenient man-machine interaction.

Multiple sound and light alarming functions

Use standard magazines, good compatibility, load with 3 magazines at one time.

Lifting distance adjustable according to PCB, 4 kinds of distance(10mm, 20mm, 30mm and 40mm)

Loader configured with inner push board component, save the cost of buying PCB moving machine independently.

Automatic counting function make it easy of production statistic

Optional SMEMA port for communication between machines.

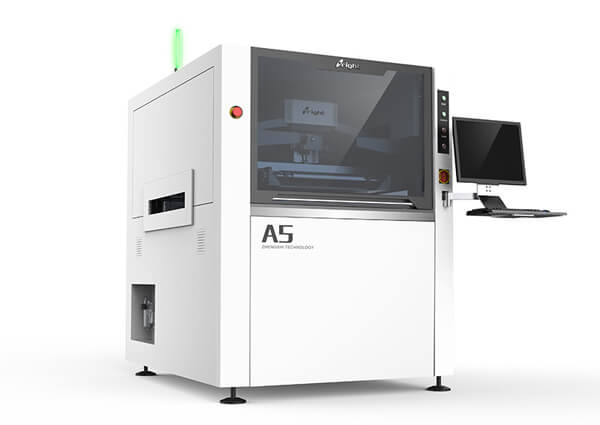

2. Automatic smt stencil printer A5

A Seriel smt stencil printer is high accuracy and high stability of the fully automatic printing machine vision,We followed in SMT industry is the development trend of production of a new generation of fully automatic printing machine with the international leading technology synchronous vision, visual processing of high resolution, high precision of the transmission system, suspension adaptive scraper.

Specification :

A Series High Precision Automatic solder paste printer designed for high precision

steel mesh printing or stencil printing in SMT industry.

Printing PCB size:50mm x 50mm ~1200mm x 800mm;

PCB thickness: 0.4mm ~ 14mm

FPC thickness: ≦0.6mm (Excluding jig)

Applicable pitches of Components

SMT Components such as resistors, capacitors, inductors, diode and triode: 0201, 0402, 0603, 0805, 1206 and other specifications;

IC: support SOP, TSOP, TSSOP, QFN packaging, min. pitch 0.3mm; support BGA, CSP packaging,

min. ball 0.2mm;

Applicable PCB Types

Applicable to PCB types of mobile phone, communication, LCD TV, STB, family cinema, vehicle electronics,

medical power equipment, aerospace and aviation, besides general electronics products.

Samsung SM481 Chip Mounter is based on the high-speed placement machine SM471 platform for the VISION system to

strengthen the same level of equipment in the fastest equipment,

It is equipped with a cantilever 10 shaft, the new flight camera and the application of the

best suction / placement action, so as to achieve the same level of products in the world as

fast as 39,000CPH. The other can correspond to a minimum of 0402 components to the

maximum □ 42mm IC, and increased practical productivity and mounting quality by applying

electric feeders, which can be shared with SM pneumatic feeders, thus maximizing

the customer's convenience of use.

4. high production Capacity reflow oven F10

1. Well-known brand computer with Siemens PLC intelligent control system, high precision temperature control in ± 1-2 °C (if the computer has gone failure accidentally, it can realize off-line mode and not affecting production) and to ensure that the control system is stable and reliable;

2. Windows XP operating platform with user friendly operation.

3. In order to ensure safety and reliability, hood opening in automatically.

4. Device is equipped with mesh belt, transport smoothly, no shaking and no deformation, which ensure smooth PCB transport. Synchronous guide transmission mechanism and SMEMA connection ensure that guide adjustable wide precision and high service life.

5. Automatic controlled chain lubrication system..

6. PID closed loop control for all heating zones independently, sequential start up to reduce power consumption)

7. Mesh/chain transmission controlled by computer, which can fulfil different kinds of PCB production criteria.

8. Visual & Audio Alarm for abnormal condition.

9. With leakage protector, ensure safety protection for operating personnel and control system.

10. The built-in UPS and automatic delay shutdown system guarantee power failure or overheat won’t harm the PCB and machine.

11. The German ERSA world leading tiny circulation heating mode, and the upper and lower independent air tiny circulation system, temperature uniformity and thermal compensation high efficiency, high efficient supercharged accelerated air duct, greatly improve the circulating hot air flow, heat up temperature quickly (about twenty minutes), thermal compensation for high efficiency, high temperature welding and curing;

12. The upper and lower every temperature zone with independent temperature inductive sensor, real-time monitoring and compensation every temperature zone balance;

13. Have password administration of the operating system, to prevent the irrelevant personnel changes to the process parameters, operation records management traceability process parameters modification, improve the management convenient. Capable for saving user existing parameters and profile printout;

14. Integrated control window, the computer switch, test or printout profile and data transmission are convenient, humanized design. Equipped with three-channel temperature profiling system, may at any time to check soldering objects by the actual temperature profile (without 3rd party profiler);

15. From international standard quick cooling system, magnifying glass type efficient rapid cooling, cooling speed can reach 3.5 ~ 6 °C/ SEC, management is very convenient; External chiller unit, ensure that spot crystal effect (Option selected items, the standard configuration for forced natural air cooling).

5. Koh Young ZENITH Alpha 3D AOI

Advanced Hardware FeaturesThe World's Best-selling & First Full 3D Automated Optical Inspection Eliminates all the sources of defects using full 3D measuring inspection equipment skills- Removes shadow problems utilizing 8-way projection- Realizes perfect 3D solder joint inspection- Provides accurate inspection data with real-time PCB warp compensation· Full 3D data-based process optimization solution: Realization of industry 4.0 smart factory- Process information DB and real-time remote monitoring- Inspection program management automation & efficiency· Optimized specification model for a variety of production environment

High-precision weld seam measurement algorithm provided by KOH YOUNG technology for artificial intelligence

1.PLC+Touch screen control , easy to operate.

2.Design with firm structure.

3.The upper and lower air clamps ensure the location of the material box accurately.

4.Special gas path design ensures that the PCB panel is not pushed.

5.Automatic detection of fault code display function.

6.With SMEMA signal.

Keywords:

Professional SMT machine supplier. If you have any needs, please contact us.

Hanwha Chip mounter:XM520, HM520, HM510, Excen PRO, Decan S2, Decan S1, SM485P, SM482 Plus, SM481 Plus, SM471 Plus

YAMAHA Chip mounter: YRM20DL, YRM20, YSM40R, YSM20R, YSM20WR, YSM10, F8S, YS12F, YG12, YG100RA, YS24F

JUKI Chip Mounter: LX-8, RX-8, RX-7R, RX-7, RS-1R, RS-1, RS-1XL,JM-20, JM-100, FX-3RA, KE-3010A, KE-3020VA

Panasonic Chip Mounter: NPM-GH, NPM-DX, NPM-D3A, NPM-D3, NPM-WX/WXS, NPM-TT2, AM100, VM101, VM102

FUJI Chip Mounter:AIMEX III, AIMEX R, NXT III, NXTR-S, NXTR-A, NXT M6 III, NXT M6 Ⅱ, NXT M3 III, NXT M3 Ⅱ,

Siemens Chip Mounter:SIPLACE XS Series, SIPLACE SX Series, Siplace DX Series, SIPLACE TX Series,

SMT Stencil Printer:GKG, DEK, JUKI, FUJI, Yamaha, Panasonic, SMT Glue Dispenser, Semi-Auto stencil printer,

SMT Reflow oven:6 Zones, 8 Zones, 10 Zones, 12 Zones, Heller, Ersa, JT

Insert Plug-in machine:Hanwha, JUKI, Yamaha, Panasonic, Offline Insert Plug-in machine, Vertical Plug-in machine, Heterotypic Plug-in machine

Wave Soldering Machine:Dual Rail, lead free, Nitrogen, Ersa, JT

SMT Inspection machine:Saki SPI/AOI, Koh Young SPI/AOI, JUKI SPI/AOI, Omron SPI/AOI, Yamaha SPI/AOI, Flying Probe Testing Machine, X-Ray Inspection Machine, In-Circuit Tester,

SMT Peripheral Equipment:PCB Loader, PCB Unloader, PCB Conveyor, PCB Transfer Shuttle Conveyor, Auto BGA Rework Station, PCB loader Buffer Stocker, PCB Cleaning Machine, SMT Nozzle Cleaning Machine, PCB Separator Depanelizer Machine, Automatic inline Labelling Machine, SMT Screen Developing and Stripping Machine, SMT Ionic Contamination Tester, SMT Camera Module Cleaning Machine, Reflow Oven Cooler Cleaning Machine, SMT Fixture Cleaning Machine, PCB Stencil Cleaning Machine, PCB Laser Marking Machine, PCB Circuit Repair Machine, Thermal Profiler for reflow oven,

SMT SPARE PARTS:JUKI Feeder, Yamaha Feeder, Panasonic Feeder, Sansung/Hanwha Feeder, FUJI Feeder, Seimens Feeder, Mydata Mycronic Feeder, Feeder Storage Cart, Tray Feeder, Feeder Calibration jigs, JUKI Nozzle, Yamaha Nozzle, Panasonic Nozzle, Samsung/Hanwha Nozzle, FUJI Nozzle, Universal GSM Nozzle, Siemens SIPLACE ASM Nozzle, Mydata Nozzle, JUKI Spare parts, Yamaha Spare parts, Panasonic Spare parts, Samsung/Hanwha Spare parts, Siemens Spare Parts, FUJI Spare Parts, Mycronic Spare Parts,

SMT WORKSHOP LINE:SMT LOADER+ SMT printer+ SMT SPI+ SMT chip mounter+ SMT reflow oven

Add: No. 4, Yangyong Industrial Zone, Shapu Community, Songgang Street, Baoan District, Shenzhen China Tel: +86 -137 14564591 Skype:sales@effsmt.com E-mail:sales@effsmt.com

Automatic Samsung SM481 SMT Assembly line was added in Jan 2024

Automatic Samsung SM481 SMT Assembly line has been viewed 10 times

20 More Products from Efficient Technology Co., Ltd :